New metallic bubble wrap is far stronger than plastic bubble wrap, and more than 50 percent more bendable than flat sheet metal. This metallic bubble wrap was designed to be more durable than regular bubble wrap and other packing materials.

Engineers at North Carolina State University invented the metallic bubble wrap as a way to improve the durability of packaging materials for electronics and suitcases, along with other products such as car doors, airplane wings and helmets, where it can also be used in the products themselves. The metal is not meant to replace traditional plastic bubble wrap, but to be used when circumstances call for sturdier cushioning.

“If you are packing a piece of glass to ship it, you may still want to use plastic,” Afsaneh Rabiei, an engineer from NC State University and lead researcher on the project, told LiveScience. “But if you are packing yourself in a car, and want to protect against car injury, this could be used inside doors, the hood, really any part of the car.”

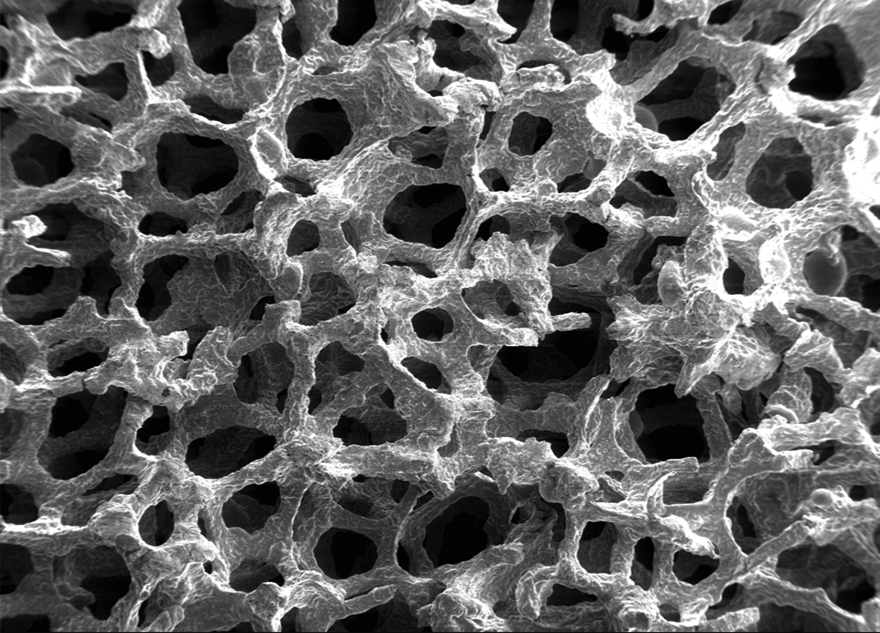

To create the material, the team pressed small depressions into thin sheets of aluminum using a studded roller. The engineers then filled the dimples with a foaming agent, covered the sheet with a flat layer of aluminum, and melded the two pieces of aluminum together with a heavy roller. Finally, they placed the merged sheets in a furnace, causing the foaming agent to decay and break down into air bubbles that became trapped within each dimple.

As the material bends, the bubbles deform and absorb energy, allowing the metal to bend more than it would without the bubbly cushion.

The team had to troubleshoot several times to figure out a way to make sure the foam did not shift before the layers were melded together, Rabiei said. This is a crucial step in the process because, if the foam leaks before the layers are secured together, air pockets develop in improper places and the material weakens.

Rabiei still has not tried to pop the bubble wrap between her fingers, but she doesn’t think it would work very well.

“It all depends on how thin of a sheet of metal you have, but I doubt it,” Rabiei said. “The point is that you are making it to be stronger than regular bubble wrap. Maybe if you bang on it with a hammer you may pop it, but I’ve never tried.”

Next, the team plans to experiment with different thicknesses and types of metals, hoping to replicate the design with steel and titanium.

The group presented their invention for the first time on June 24 at the 8th International Conference on Porous Metals and Metallic Foams in Raleigh, NC, and they are in the process of publishing their first scientific paper describing it. The project is not yet funded, and the team is waiting for funding before moving further in development.