Transport packaging and their contents are influenced by the modes of transport. Depending on which transport mode that is used, packages will be exposed to different kind of stresses. The main stresses are;

1. Mechanical Strains – The most common mechanical strains on transported goods are force stresses like, stacking pressure and shocks and energy stresses like vibration and dropping.

2. Climatic Stresses – Climate plays a vital part for the durability and performance of the packaging during the transport.

Transportation Modes

The method of transportation presents a number of potential strains on the packaging. Below are examples depending on transportation mode;

| Sea Freight |

Rolling, Lifting, Pitching, Yawing, Jarring |

| Air Freight |

Acceleration, Retardation, Lifting, Dropping, Pitching, Jarring |

| Rail Transport |

Acceleration, Shunting shocks, Centrifugal forces, Jarring |

| Road Transport |

Acceleration, Retardation, Centrifugal forces, Jarring |

Click here to learn the pros/cons of the different Modes of Transport.

Testing Methods

Packaging is tested in two ways; 1) regarding their material performance, but also, 2) how they perform during the actual transportation. Below are some examples

Transportation Packaging Testing

A transportation testing program is divided into different stages which follows the distribution chain. The testing programs represent the “highest normal” strains that will occur during a transport. The different tests that can be performed are described below;

· Drop Test, ISO 2248 – The test simulates actual shocks by dropping the package and its content freely against a rigid plane surface from a predetermined height. For example, a drop test can be conducted so that the package hits the surface diagonally against one corner, as in the picture beside.

· The Compression and Stacking Tests, ISO 12048 and 2234 – This test is performed to assess the ability of a transport package to withstand compressive forces and to protect its contents during compression. The test may also be used as a stacking test to investigate the performance of i.e. the bottom package in a stack during storage in a warehouse.

· The Vibration Test, ISO 2247 and 8318 – Various forms of transportation vibrations can be simulated in a laboratory through a vibration test. The test-bench can be made to swing and vibrate in almost any direction with a number of frequencies and amplitudes to emulate the transportation being used.

· The Horizontal Impact Test, ISO 2244 – Horizontal shocks are simulated by applying a horizontal velocity to the test specimen and bringing it to halt by impact with a vertical impact surface.

· The Water-Spray Test, ISO 2875 – The test is designed so that each area of the top surface of the package is sprayed with water maintained at a constant temperature at a specified rate for a specified period. The test package shall be filled with its intended contents and closed normally, as if ready for distribution.

· The Rolling and Toppling Test, ISO 2876 AND 8768 – In a rolling test the package is placed on a horizontal impact surface with the resting surface down. The package is tilted until the point of balance on this edge is reached. Then it is permitted to overbalance without thrust so as to impact on the surface. This procedure shall be repeated until all six sides have been impacted.

Packaging Material Testing

Material tests are used for all kind of materials used as packaging material. Here are examples of tests used to qualify plywood for our own produced NEFAB ExPak and NEFAB RePak products. The tests are;

- Bending Test-EPU: 4/86:89 – the ability of the package to withstand compression is based on the bending strength and bending stiffness of the sheet material. Therefore this is a vital test to perform in order to get the best possible packaging.

- Moisture Absorption Test – In order to determine the plywood box’s capability to protect the goods from moisture and to establish how moisture resistant the actual box will be a moisture absorption test is performed on the different batches of plywood used.

- Cutting–strength test, BS 6566:part 8:1985 – The cutting-strength test is performed to establish the strength of the glue, which holds the veneers of ply together to form the plywood-sheet. The testing methods vary a bit depending on the bonding material used in the plywood.

- Testing of Glue–Joints, SS 84 20 21:mom 6.1 – This test is very similar to the one used to measure the strength of the plywood. However, unlike that test the pressure is applied on both sides of the glue-joint, in order to get the maximum strain on the joint.

- Joint Test, sheet/steel(tongues and klammerband) material – The aim of this test is to determine the strength of the joint between the steel and the sheet material.

Testing Standards

There are a number of different testing standards on the market and each standard has different severity levels. The important thing when choosing the right standard and the right severity level is to have a dialogue between all the concerned parties. The following standards are some of the most frequent standards for transportation testing on the market;

- ASTM : American Society for Testing and Materials

- ETSI : European Telecommunications Standards Institute

- ISO : International Organisation for Standardization

- ISTA : International Safe Transit Association

- TELCORDIA : Telcordia Technologies (former Bellcore)

Packing materials vary from a simple bubble-wrap to protect the vase you are sending your Aunt Jenny for her birthday, to industrial strength materials able to withstand being dropped from a crane while unloading them. Testing packing materials to determine how well they stand-up before they leave the factory or local post-office helps reduce the chances of the articles getting damaged on the way and the industry having to pay for expensive returns and replacements. The standard tests for packing materials include the drop, compression, horizontal impact water spray, material bending, vibration and joint or glue tests.

Instructions

l Determine what you want to test the material to withstand. This may include surviving vibrations or ability to withstand the impact of being dropped when being unloaded from a ship. A home test could be wrapping the vase and dropping the package to make sure it does not break.

l Find out what means of transport is going to be used because this will help you determine the “highest normal” strains that the packing material will be subjected to. Sea transport, for instance, may require waterproof packing materials that are able to withstand rolling and pitching, whereas sending things by semi-truck may require packing materials that can be stacked on top of each other and subjected to jarring.

l Decide if one test is enough or if a series of experiments over time would give you a more accurate indication of how well the packing material performs. Record your test outcome so you can compare initial and future test results.

l Calculate if testing packing materials warrants purchasing your own equipment or if it is more economical to hire a materials testing business to do it for you. Another way you can test the packing materials is to actually send them out and see how many are damaged, which is what is likely to be the packing materials test with Aunt Jenny’s present.

Take a look at this cute bubble wrap Snow Man!!! It’s such a cheap and great idea! All you gotta do is just roll those things up into 3 big balls and then just decorate then the way you like. AWESOME!! I’m thinking if I should do this. I love the idea. What do you guys think. Do you like them as much as I do?

It’s so simple — so gloriously simple. In 2008, China instated a law that made it illegal for stores to give out plastic bags for free. Instead, shop owners were required to charge for the bags, and allowed to keep any profit they made for themselves. The results? After two years, the poorly-enforced law has nonetheless dropped plastic bag consumption by a whopping 50% — keeping an estimated 100 billion plastic bags out of the landfills.

It’s a beautiful demonstration of how a simple piece of policy can achieve big results — while keeping everyone (except perhaps the plastic bag manufacturers) happy. Small business owners make a small additional profit, consumers learn to reuse bags, and the environment, of course, emerges the biggest winner of all.

GOOD points to a Chinese student’s research on the ban, and how it impacted consumer behavior. Here are his findings:

Consumers in Beijing and Guiyang used an average of 21 new plastic bags weekly before the bag-fee ordinance was passed in June, 2008, and rarely used the same bag twice. But after the law was imposed, consumption dropped 49 percent and nearly half of the bags were re-used. While that represents a significant reduction, researchers say there is much room for improvement, especially when it comes to enforcement. Months after the law was enacted, the researchers say, nearly 60 percent of all plastic bags were still given away free.

So the law is impressively effective even with piss-poor enforcement. I’ll turn to GOOD’s Andrew Price for the takeaway: “After its first year, The Guardian reported the ban had saved the country 40 billion plastic bags. By now the cumulative number of bags saved is probably more like 100 billion, and if the law were enforced well, it’d be a lot higher.” Yes indeed — with those kinds of results, seems it’s high time we started pushing a little harder for similar policy models (we already have some cities that charge a tax for plastic bags) here in the states.

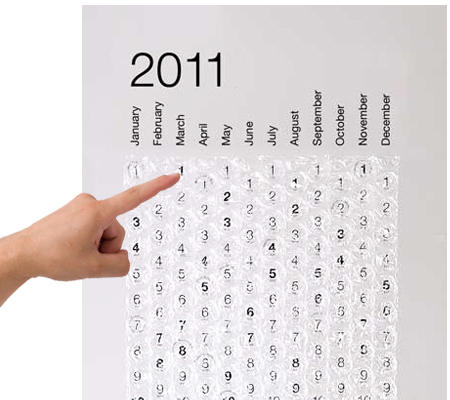

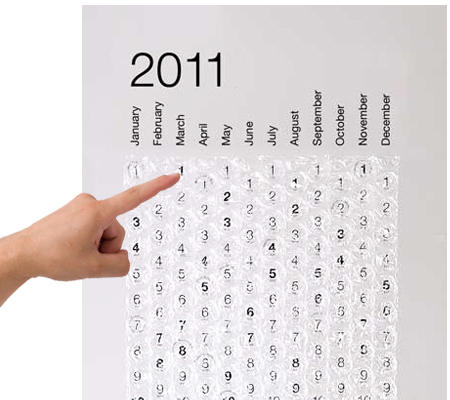

This has to be the best thing I’ve seen all week! Everyone loves popping bubble wrap! It’s literally just a numbered piece of bubble wrap on a piece of poster board (at least that’s what I assume “glossy cover stock” is). I’m not entirely sure that the dates have the day of the week on them but even still, it’s pretty neat!

It probably wouldn’t be hard to make yourself. Just get poster board and affix the bubble wrap you’ve numbered yourself (writing backwards don’t forget) and either, type up and glue, or write by hand, the months because $20 really is kind of a lot to spend on bubble wrap and poster board. Why couldn’t I have thought of something like this to sell!

But the question is, how are you sure to get it sent to you with out a bubble being popped along the way?

If you work at an office job you know how stressful work can be, If your one of those people that needs a way to relive stress how about taking it out on your tie, bubble tie that is. haha now i dont know about you but i could burst those bubbles all day so this is genius to me 😀 , i dont exactly know what you would do after all the bubbles are burst but you probably just replace the bubble wrap? lol … what do you guys think cool or just stupid?

If you have taken the time to go out and buy a present for someone then you want them to get it in the condition it is intended to be in. Whether it is an anniversary present for your partner, a birthday present for a sibling or something for a friend for Christmas, you have put the thought and effort into buying it so you should do the same when wrapping it. You need to make sure the gifts are protected and bubble wrap can come in extremely useful when wrapping presents that are fragile and could break with a slight bump or if the package is dropped. Clearly, the worst thing that could happen is that the person opening the present does so and then finds that what you have bought them has been damaged or even completely broken. You should therefore make sure that you take a bit of time when wrapping to prevent this from happening.

Obviously, the amount of cushioning you give when packaging your gifts is going to depend on two main things, how it is getting to the person it is intended for and most importantly the item itself. If you are going to be dropping off or giving the present to the person yourself then you will not have to worry as much about the protective layers. This is because you are obviously going to know what is inside and will take a sufficient level of care when transporting it. On the other hand, if you are sending your gift via a courier or through the Post Office then you are going to have to put a lot more padding on your fragile items. This is due to the fact that it will be getting handled a number of times and the people who come into contact with it will not necessarily know to be more careful with your package.

When it comes to the actual item that you are wrapping then a bit of common sense should be applied. If you are sending clothing or something that cannot really be broken or damaged in transit then you don’t really need to add any cushioning as it would be unnecessary. However, if you are sending anything made with glass parts or anything else that could easily be broken then you must ensure that you do all you can to protect these items. By adding a couple of layers of bubble wrap in and around your gift, you can prevent breakages occurring from all but the most major of impacts.

From June 1 Recently I visited the Cheung Sha many large supermarkets, shopping malls found that early accumulation of plastic bags to spare, many consumers are too many things not fit to the ground, requiring cashiers to give plastic bags the situation have occurred.

people know, ultra-thin plastic shopping bags has two advantages, one is convenient, eliminating the possession of tired; the other is health, low-cost plastic bags, put things can be categorized into different bags, in line with modern hygiene. Therefore, after the invention was widely used business, free of charge to home shoppers,air classics bw, and consumers carry the thing home, the cheap plastic packaging these as spam, readily lost.

However, from an environmental point of view, can be said that plastic bags are the worst 20th century invention, this invention brings to our living environment a lot of adverse consequences. In our countries, for example, every day spent only in the markets should more than 1 billion plastic bags, all kinds of other ways to use up at least 2 billion plastic bags or more. These plastic bags in convenience to people’s lives, but also became the Therefore, adherence to the modern concept of sustainable development, we must limit use of plastic bags.

free plastic shopping bags became the product concerns. For the However, if no suitable alternatives, all the inconveniences in daily life is bound to adequate food and clothing for a just country, the daily life of ordinary people still need careful planning. People go to the supermarket next to the food market, what to packaged food? Can the emergence of alternatives to facilitate the extent possible to meet people’s needs? Will increase the financial burden of the people? Promoting alternatives,air max 1 sale, government, businesses, consumers,air max 90 on sale, who should bear more of the responsibility? These problems are not resolved, the our happiness, Xinhua recently reported that AQSIQ Pu Changcheng, deputy director of the State Council Information Office held a news conference, said the AQSIQ to support alternatives to plastic bags research, and develop appropriate standards to respond positively to the implementation of the system of paid use of plastic bags; so that people can not only really abandoned plastic bags, to meet environmental protection needs, and also enjoy the convenience and benefits, like plastic bags.

“Never judge by a book by its cover”, we have often heard these words of words wisdom. But think carefully, the first impression we get of a product is inevitably its packing isn’t it? After all this is expected since the first thing we see is the packaging! Thus, it is very important for suppliers and marketers of products to choose the proper packing to enhance the image and value of the products to secure a premium price as well. Imaging aside, product packaging is a vital part of your product delivery and value chain as it acts as the vehicle for the product to reach the hands of the final customer. This is critical as improper packaging, be it in size or material leaves a good chance for the product to get damaged or contaminated. Thus specialist packaging such as foam lined boxes for fragile items to cardboard tubes and doubled walled cardboard boxes providing more support for the heavier or larger products are available on the market according to your choice.

It isn’t easy deciding on packaging, in fact it is one of the most carefully thought about decisions management makes, as the cost of packaging is a direct cost and (quite commonly) constitutes an appreciable proportion of the total product cost. So the dilemma is how to find a high quality and cost effective post and packing system which caters to your specific needs. So how do we decide where to buy post and packaging, specially for commercial purposes? As this is a market with a large number of potential sellers, the high quality ones need to be filtered out from a gamut of options. Thus the availability of information is an important deciding factor. So the internet is a very good place to start as it is extremely transparent about the full range of products on offer and the prices they are available at. Further a lot of suppliers offer tailored services when it comes to packing supplies, these details are also commonly available online, or they entertain requests for information with regards to their products. So you can peruse through the complete range of options available to you before a decision is made. This process is facilitated by internet firms offering packaging supplies.

Online packaging supply firms have increased in number with the need for tailor made commercial post and packaging has booming in the recent past as e-bay sellers and various small firms have begun offering their products (sometimes exclusively) online. The commonly sought after types of packaging products and accessories include Packing Boxes, Kraft Paper Rolls, Silica Gel Packs, Telescopic Boxes, Sealed air bubble Wrap, Aircap bubble wrap, Mail Lite Padded Envelopes and Polythene Bags. Some (or most) of these products are, although commonplace, specialized for the products they are designed to pack. Thus it is important for companies to select a supplier that is quick on the delivery, is easy to contact, and is tailored to your specific needs. What better than to select an online packaging supplier? There are high quality websites offering a whole range of products for very reasonable prices. And the best part is, most of these products are tailor made to your exact specifications. Most sites offer free guidance on selecting the optimum packaging solution for you as well. Thus your needs for high quality packaging and postage accessories can be met at a reasonable rate without spending much time and effort searching out a shop!

Please find more information about Packing Supplies from http://www.postandpackaging.com

The Indian Institute of Packaging successfully concluded the two weeks Global Residential Training Program on Packaging Technology. The main objective of this training program was to disseminate information about the latest trends in packaging, packaging materials, its innovations and their applications in various sectors. The training program was organized for the benefit of the participants to highlight the role of packaging in the promotion of business growth, merchandising and its impact on the overall economic development of the nation. 14 delegates from six APF member countries like China, Sri Lanka, Thaliand, Singapore, Bangladesh and India had traveled to India to attend this program. In addition to theoretical class room sessions, visits to reputed packaging industries in and around Mumbai were also organized to provide the delegates with a first hand knowledge about the operational aspects of the various packaging materials.

Packaging is considered to be one of the largest and the most diverse manufacturing sectors in the world with a value of more than US$550 mln and an employment for around 5 million people with more than 100,000 companies engaged in this sector worldwide. The Asia Pacific region has become the 3rd largest packaging market and the average annual growth rate is about over 5-6 %. In the global scenario, the packaging sector ranks 9th among the top 10 industries in the developed nations.

Mr. Saha, Director, IIP stated “The Indian Packaging industry has been growing at the rate of 10 – 12% with an annual turnover of USD $13 billion or Rs. 650 billion and is expected to reach to Rs. 850 billion or USD 18.5 billion by 2015. The plastic packaging industry is still growing at the rate of 20-25% despite the negative publicity that the industry draws due to its impact on the environment. This is mainly because of its easy availability, high barrier properties for food products to enhanced shelf life, printability, convenience features and most importantly cost effectiveness. Almost 40% of packaging materials are consumed for processed food products and about 18% for beverages, 5% for pharmaceuticals, 3% for cosmetics and the balance for other products. India being the second largest country in Asia next to China, in terms of population and geographical area, the 4th largest economy in terms of purchasing power parity. The country has seen a rapid growth in the IT industry, largest player in software and BPO services. The country has got a huge potential for the consumption of packaging materials due to the large base of population.” This trend has resulted to an increase in the consumption of packaging materials. But consequently the society at large is now concerned about the difficulties faced by the nations about collection, segregation and disposal of packaging solid waste. Hence a great challenge lies ahead for all the global packaging professionals to develop an effective mechanism and system for the disposal of packaging solid waste and to reduce the carbon foot print in order to contribute to a healthy environment and a sustainable society.

|

|